- GST No. 09AKUPM3849D1ZN

- Send SMS

- Send Email

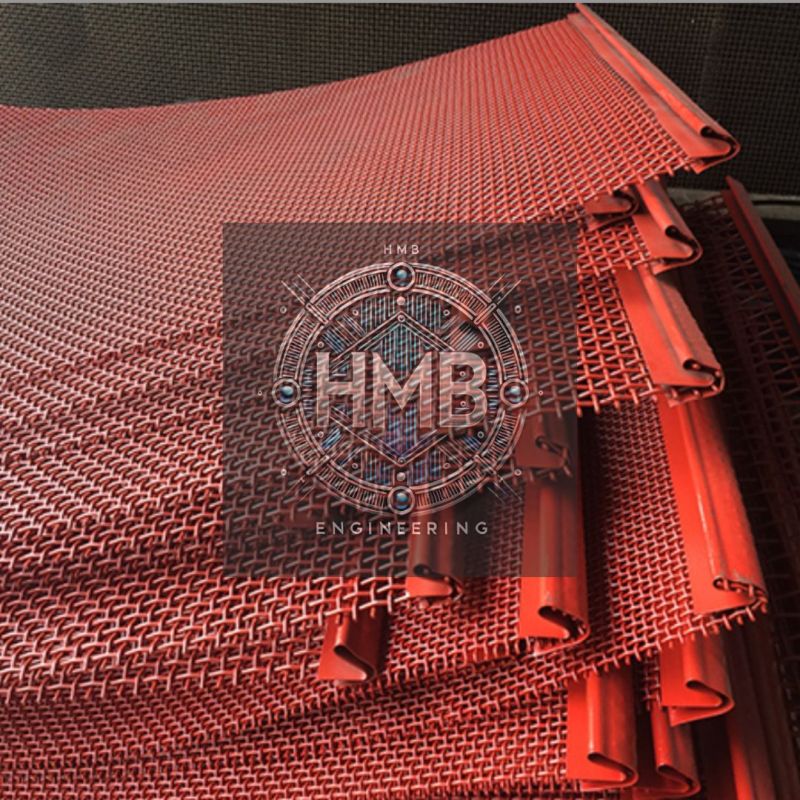

Steel Screens

Leading Manufacturers, Exporters, Wholesaler and Retailer of Crimpe Wire Mesh Screen, Crusher Screens, Filter Screen, High Carbon Steel Mining Screen, PU Flip Flop Screen, PU Modular Screen, Stainless Steel Screen, Steel Wire Mesh Screen and Vibrating Wire Mesh Screen from Ghaziabad.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | High Carbon Steel |

| Weave Style | Crimped |

| Wire Diameter | 0.5-10mm |

| Min. Order Quantity | As per Client requirement |

| Supply Ability | 1000 Piece/Pieces per Month |

| Packaging Details | or as special request or as your special require. |

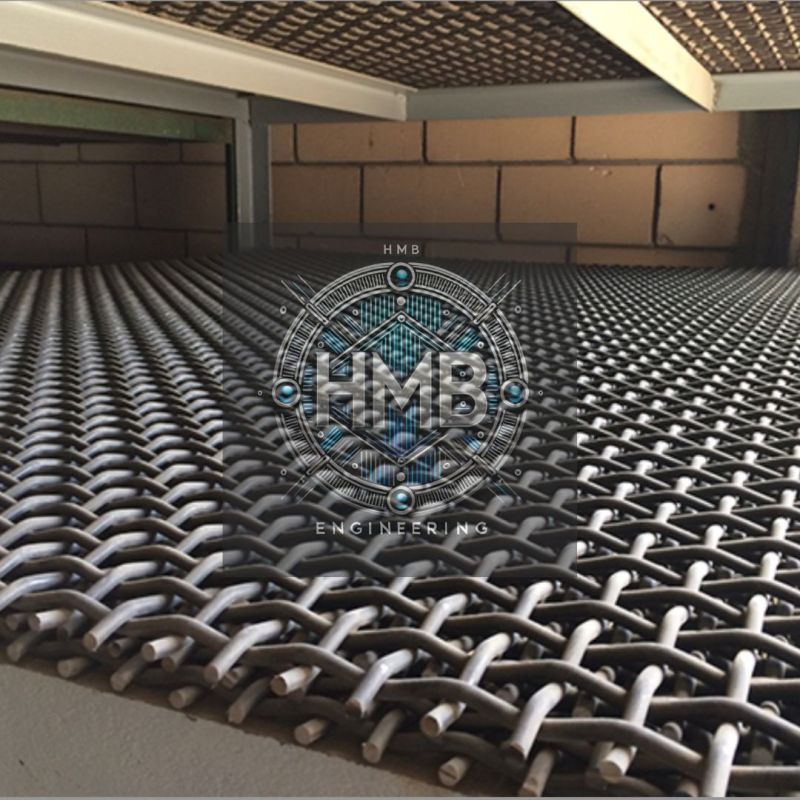

Flat top crimped

Flat top crimped, also called pressed crimped, is made from round and profiled plain weave wire. All the mesh knuckles is being on the underside. The structure is very heavy and durable. The smooth surface is the characteristic of the weaving method. This structure can allow the materials to move more freely over the screen. It is widely used in the vibrating screen.

Lock crimped

Lock crimped is a refinement of the intermediate crimped. It can lock the wire at their position through pressed at each side of the raised wire. This structure can add the stability of the crimped woven wire mesh.

Double crimped

Double crimped is also called plain weave. Different from the intermediate crimped, both the warp wire and weft wire are woven directly by straight wire. We can get a rigid construction through evenly crimp in warp and weft wire. The wires are under crimped and sprung together thus giving a tight mesh. This is used mainly with lighter wires to ensure tension in a light screen

Intermediate crimped

Intermediate crimped can be divided into single intermediate crimped and double intermediate crimped. The single intermediate crimped means the weft wire is pre-crimped and the warp wire is directly woven. The double intermediate crimped means both the weft wire and warp wire is pre-crimped and then woven together.

Pre-crimped process

Using the precision machine, the intermediate crimped wire is pre-crimped by the rotary dies. The pre-crimped wire can assure the spacing of the wires. When the wires are woven together, the structure can ensure the wires will lock firmly together at the intersections.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | High Carbon Steel, High Tensile Spring Steel |

| Wire Diameter | 0.71mm - 14mm |

| Opening Size | 1mm - 110mm |

| Mesh Type | Square, Rectangular Slot, Long Slot |

| Surface Treatment | Black or Red Color Painted |

| Edge Preparation | Plain, Bent or Hook |

| Hook Type | C or U hook for 30-180 |

| Weaving Type | Double Crimped, Intermediate Crimped, Flat Top Crimped and Lock Crimped |

Features

- Wear and abrasion resistance

- High temperature resistance

- High tensile strength and toughness

- Options in opening sizes to fit almost equipments

- Excellent stability of the vibrating screen improves the separating efficiency

- Heavy impact resistance

- Long service life

- Corrosion resistant

- Weather proof

Applications

- Coal industry

- Mineral industry

- Agriculture industry

- Construction industry

- Metallurgy industry

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Wire Diameter | 0.020mm - 2.03mm |

| Mesh | 1 Mesh - 635 Mesh |

| Width | 0.5m - 6m |

| Shape | Round, Rectangle, Ring, Oval, Cone |

| Construction Material | Stainless Steel, Copper, Aluminum |

Available as

- Filter tube

- Filter disc

- Shaped mesh filter

- Sintered filter mesh

- Mesh filter cartridges

Features

- Non toxic

- Environment friendly

- Resistant to corrosion and rust

- Can be divided into single or multi layer

- Excellent filtering efficiency

- Abrasion and wear proof

Applications

- Petroleum industry

- Pharmaceutical industry

- Food industry

- Water treatment plant

- Paper making industry

- Chemical industry

- Plastic recycling

- Pharmaceutical industry

Used for

- Filtration of air, water, liquid

- Medium cleaning

- Flow control of lubrication

- Sink strainers

- Filter dryers

- Centrifuges

- Fluid bed dryers

- Dust collectors

- Hydraulic pressure and air pressure system

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Feature | Durable, High Quality, High Strength, Solid |

| Condition | New |

| Shape | Square |

| Material | Carbon Steel |

| Application | Industrial Use, Woven Wire Mesh |

| Number Of Flower | High Carbon Steel Mining Screen |

| Wire Grade | 45 to 70 |

| Weaving Type | Single Intermediate Crimp, Double Crimp, Double Intermediate Crimp, Lock Crimp |

| Sift a dip angle | 15~55 |

| Amplitude | 0.6~2.2 |

| Capacity | 100 sets/month |

HMB Engineering brings you High Carbon Steel Screen Mesh built for relentless use in mining mills and tough jobs. Honestly, that first glance at our High Carbon Steel Screen Mesh and you sense rugged reliability for crushers and sieves alike.

Engineers love it. Welded seams and tough steel resist abrasion, even under heavy stone flow. This is what robustness means. You know what? Wear‑and‑tear becomes a distant worry when you install this high‑carbon screen mesh. It handles grit, dust, and impact like a champ.

HMB Engineering is a recognised leader—Manufacturers and Suppliers of quality products for the last decade. You get consistent pore sizes and longer wear life. Seasonal rain or summer heat, the mesh holds its shape and filtering efficiency doesn’t flinch.

Need heavy‑duty filtering down to fine particles? High Carbon Steel Mining Screen by HMB Engineering keeps operations smooth. This screen is not your everyday grid. It’s engineered for mining grit, heavy flow, and that constant hum of vibrating table action.

Imagine fewer replacements, fewer pauses, and better throughput. That buzz when it works keeps the plant alive. Why settle for second‑rate screening? Choose HMB Engineering’s high‑carbon steel mesh and feel sturdy, reliable performance every cycle.

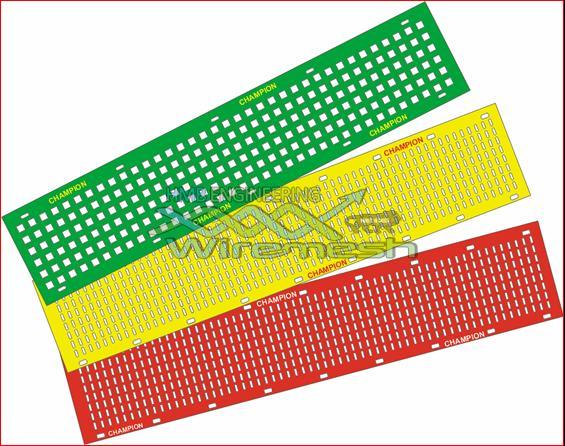

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Panel Size | 610mm x 300mm (24" x 1113/16") 305mm x 305mm (12" x 12") |

| Aperture Size | 0.35mm x 80mm-(1/70" x 31/8") |

| Pack Type | Carton Box |

| Condition | New |

| Warranty | 1 Year |

| Feature | Durable |

Used for

- Mining Industry

- Steel Plants

- Cement Plants

- Mineral Beneficiation Plants

- Coal Washeries

- Power Plants

Applications

- Secondary Tertiary & Final Screenings

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Wire Gauge | 2.5 mm |

| Panel Size | 610mm X 300mm (24" X 1113/16") 305mm X 305mm (12" X 12") |

| Aperture Size | 0.35mm X 80mm-(1/70" X 31/8") |

| Aperture size | 1/70 |

| Weight | 2.5 kg - 8 kg |

| Thickness | 5-10 mm |

| Hardness: | A-85 to a-90 |

Used for

- Cement Plants

- Steel Plants

- Mining Industry

- Power Plants

- Mineral Beneficiation Plants

- Coal Washeries

Applications

- Secondary Tertiary & Final Screenings

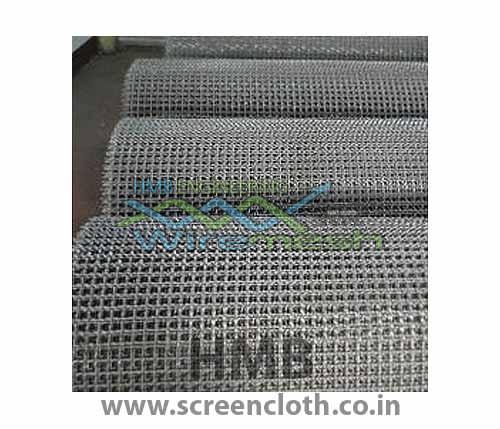

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Material | Stainless Steel |

| Thickness | 0.5-1mm, 2.5-3mm, 3.5-4mm, 4.5-5mm, 5.5-6mm, 6.5-7mm, 7.5-8mm |

| Length | 100-200mm, 200-300mm, 300-400mm, 400-500mm |

| Finishing | Polished |

| Features | Corrosion Proof, Excellent Quality, Fine Finishing, High Strength, Perfect Shape |

| Stainless Steel Wire Materials | 302, 304, 304l, 316, 316l |

| Weaving Method | One-way Crimp, Crimp and Intermediate Crimp Lock |

| Material of Construction | High Carbon Steel Wire, Stainless Steel Wire, Iron Wire, Medium or Low Carbon Steel Wire, Brass Wire |

Features

- Stable and robust

- High temperature resistant

- Resistant to alkali and acid

- Anti- corrosion

- Wear resistance

- Can sustain in the demanding conditions involving cold, heat, solvents, liquids, chemicals, and even sand and filter media

- High abrasion resistance

- Increased ability to resist pitting and crevice corrosion

Applications

- Coal industry

- Mining industry

- Construction industry

- Food processing industry for curly grilling food, flour and meat

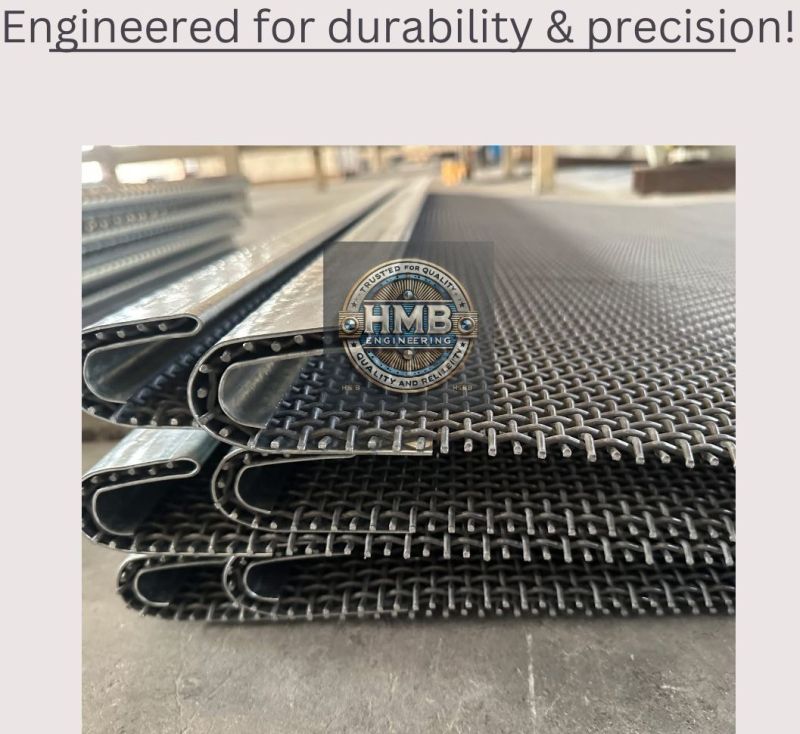

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Range of Production | 1 Mm to 150mm |

| Wire Size | 0.50 Mm to 12 Mm |

| Material of Construction | Spring Steel, Stainless Steel and Mild Steel |

| Edge Preparation | K-1, K-2, K-3, K-4, K-5, K-6, K-7 S, U |

| Crimp Type | Double Crimp, Intermediate and Lock Crimp |

| Standards | IS-2405, Part-I & BIS |

Features

- Resistant to corrosion

- Can resist breakage due to vibrations

- Chemical resistant

- Sturdy and tough design

- Large open area

- Excellent stability

- Resistant to abrasions

Applications

- Metallurgy industry

- Mining industry

- Construction industry

- Cement industry

- Ceramic industry

- Glass industry

- Plastic industry

- Petrochemical industry

- Coal factory

- Water treatment plant

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Weave Style | Plain Weave |

| Grade | IS4454 |

| Application | Construction |

| Brand | TATA MAKE |

| Material | Stainless Steel, High Carbon |

| Packaging Type | Black |

| Range of Production | 0.5mm to 150mm |

| Wire Size | 0.3mm to 16mm |

| Edge Preparation | K-1, K-2, K-3, K-4, K-5, K-6, K-7 S, U |

| Crimp Type | Double Crimp, Intermediate, Dovex, Lock Crimp |

| Weave Type | Plain Dutch Weave, Plain Weave, Twill Weave, Reverse Dutch Weave, Twilled Dutch Weave, Panel, Cable |

| Payment Terms | L/C, T/T |

Need a Vibrating Wire Mesh Screen that won’t conk out? HMB Engineering built these for non‑stop action. The moment you install our Vibrating Wire Mesh Screen, you feel confident. No sag, no dull spots, just solid performance under vibration.

You know what? That steady hum in the plant? Our mesh works silently within, while keeping particles flowing. HMB Engineering stands among the top Manufacturers and Suppliers of quality products. We make sure each mesh panel resists fatigue and carries heavy loads without bending.

Picture seasonal grit, wet sand, fine dust—our screen field‑tests show it handles all without clogging or deformation. When conveyors vibrate, you want mesh that stays tight, keeps filtering fast, and doesn’t send you chasing blockages every hour.

Our vibrating mesh uses high‑tensile materials and robust welds. That means fewer replacements, more uptime—your production schedule thanks you. Plus, installation feels almost easy. Even under sweaty summer conditions, panels click in firmly.

If you’ve seen mesh fail mid‑day, you know the hassle. Switch to HMB Engineering’s Vibrating Wire Mesh Screen and skip that drama. Want longer run times and smoother screening performance? Drop us a line. We’ll match you with a mesh built for rhythm, grit, and real‑world impact.