- GST No. 09AKUPM3849D1ZN

- Send SMS

- Send Email

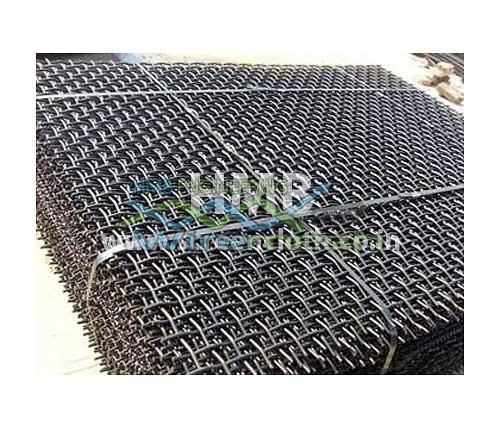

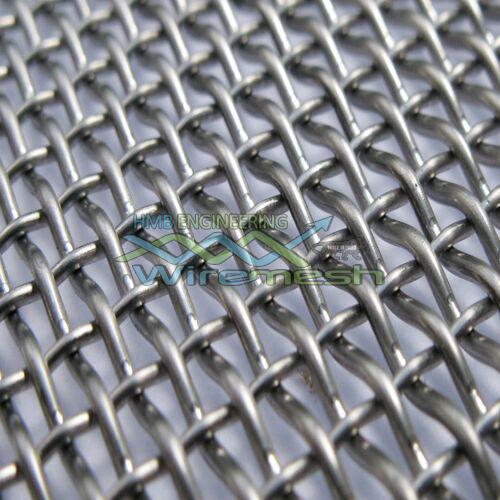

Spring Steel Wire Mesh

When you search for SS Wire Mesh Suppliers, HMB Engineering pops up with quality you can trust. Got projects needing stainless precision? Our Spring Steel Wire Mesh Supplier handles tension and flex like a champ. You know that reassuring metal sheen under sunlight? That’s our SS Wire Mesh shining bright.

Spring Steel Wire Mesh resists deformation and bounces back under pressure. Our SS Wire Mesh Suppliers deliver sheets with fine tolerances and tactile confidence for filtration, separation, or shielding.

Feeling that crisp spring‑like snap when you press it? Pure assurance of resilience. HMB Engineering stands as top SS Wire Mesh Suppliers in India, balancing flexibility and strength. Our Spring Steel Wire Mesh Supplier adds extra durability by heat‑treating steel for optimal spring response.

Need fine mesh that resists fatigue and corrosion? You’ve found the right team. SS Wire Mesh Suppliers like us offer customisation for mesh count, wire diameter, weave pattern. Seasonal weather, acid fumes, or outdoor rigs don’t faze our Spring Steel Wire Mesh.

We blend craftsmanship and consistency — you won’t get surprise failures. Curious about lifespan? Expect years of performance, minimal maintenance, and consistent results.

That’s why HMB Engineering ranks top among SS Wire Mesh Suppliers for industrial, architectural, and food‑grade uses.

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Spring Steel Wire Mesh,Decorative Wire Mesh |

| Material | Alloy Steel,Steel,Galvanized Steel Wire |

| Application | Construction Wire Mesh,Fencing And Wall Decorations. |

| Color | Black |

| Feature | High Performance |

| cetification | Iso Certified |

| Country of Origin | India |

| Weave Style | Plain Weave |

| Wire Diameter | 1-5mm,5-10mm,0.5mm-2.5mm |

| Wire Gauge | 1-5mm |

| Brand Name | TATA WIRES |

| Condition | Good |

| Min. Order Quantity | As per Client requirement |

| Business Type | Manufacturer, Exporter, Supplier, Retailer |

| Type | Spring Steel Wire Mesh, Decorative Wire Mesh |

| Wire Diameter | 5-10mm, 0.5mm-2.5mm |

| Material | Alloy Steel, Steel, Galvanized Steel Wire |

| Application | Construction, CRUSHER SCREEN WIRE MESH |

| Brand Name | TATA WIRE |

| Color | Black |

| Grade | IS4454 |

| Feature | Easy To Fit, Good Quality, High Performance |

| Condition | Good |

| Min. Order Quantity | As per Client requirement |

| Product Code | HMBSPST |

| Payment Terms | L/C, T/T |

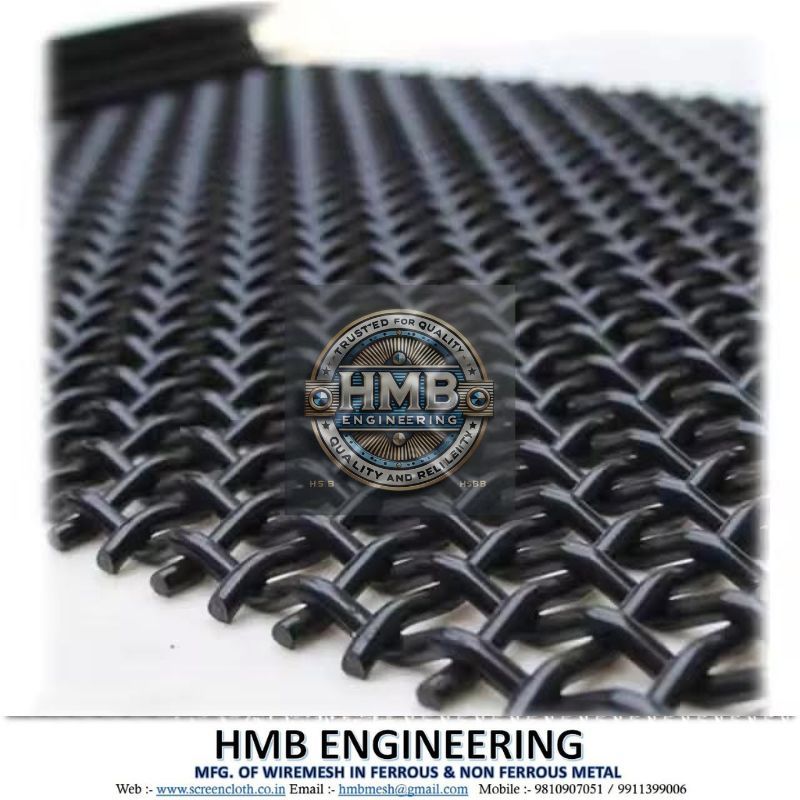

Spring Steel Wire mesh is extensively used in industries as screen deck for crusher screen, vibrating screen, quarrying screen, mining screen and other machines.

Specification:

- Material: Galvanized Steel Wire

- Wire Diameter: 0.5mm-2.5mm

- Type: Decorative Wire Mesh

Features:

- No distortion on high impact

- Can resist vibration

- Suitable for highly corrosive conditions

- Wear & tear proof

- High resistance against abrasions

Applications:

- Coal industry

- Power plant

- Chemical industry

- Mining industry

- Cement industry

- Quarry

- Iron ore industry

- Metallurgy industry

| Business Type | Manufacturer, Exporter, Supplier |

| Brand | TATA MAKE |

| Material | High Carbon Wire Mesh |

| Color | Black |

| Application | Construction, Grading,Scalping |

| Grade | IS4454 |

| Feature | Corrosion Resistance, Easy To Fit, Perfect Finish |

| Technique | Weaving |

| Weave Style | Plain Weave |

| Wire Diameter | 1-5mm, 5-10mm |

| Type | Vibrating Screen Mesh |

| Country of Origin | India |

| Wire Gauge | 1-5mm, 5-10mm |

| Product Code | HMBSPST |

| Port | INTKD6 |

| Payment Terms | L/C, T/T |

| Delivery Time | WITHIN 7 DAYS |

| Packaging Details | WIREMESH PACKED IN IRON PALLETS |

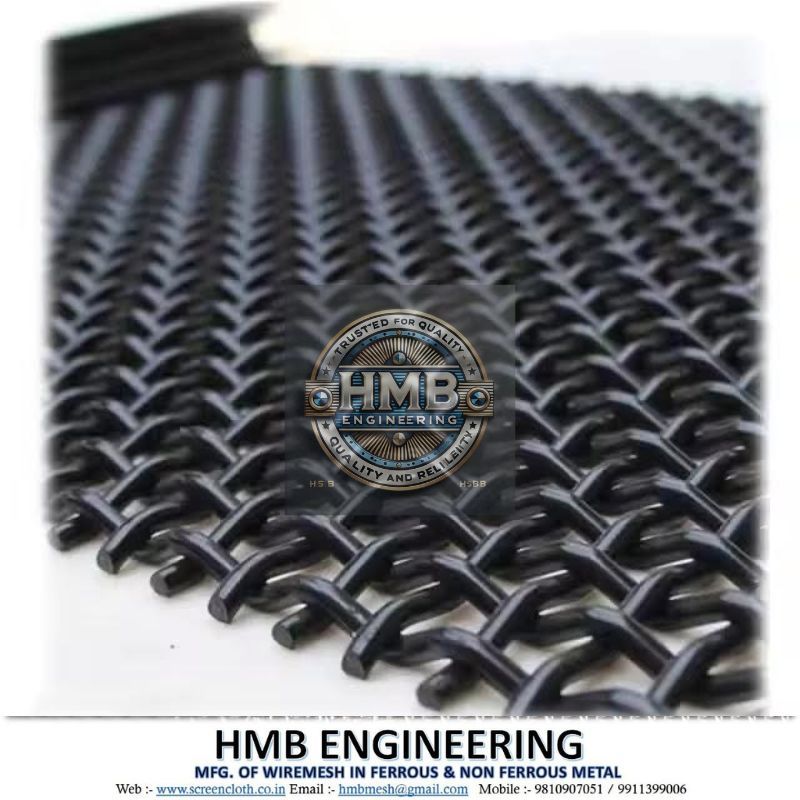

A vibrating screen mesh, also known as a sieve mesh or screen cloth, is a crucial component of a vibrating screen. It is a woven metal or synthetic mesh structure that is used to separate and classify particles based on their size. The vibrating screen mesh is stretched tightly across a frame and is designed to vibrate vigorously, allowing the material being screened to pass through the openings in the mesh while retaining larger particles.

The vibrating screen mesh is available in various materials, such as stainless steel, high-carbon steel, and synthetic materials like polyurethane or rubber. The choice of material depends on the specific application and the characteristics of the material being screened.

The mesh size of a vibrating screen refers to the number of openings per linear inch or millimeter. Different mesh sizes are used to achieve different levels of particle separation. Finer mesh sizes are suitable for screening smaller particles, while larger mesh sizes are used for coarse particle separation.

Vibrating screen meshes find applications in a wide range of industries, including mining, construction, agriculture, pharmaceuticals, and recycling. They are utilized to efficiently sort, separate, and classify various materials, such as minerals, aggregates, ores, chemicals, plastics, and more.

By using vibrating screen meshes, industries can achieve precise particle separation, improve process efficiency, and enhance overall product quality.